Biscuit Machine Plant

| Soft Dough Biscuit Equipment A rotary moulder is a machine commonly in use for producing biscuit dough pieces from short doughs. The dough to be moulded is fed into the hopper and forces the dough into the cavities of the moulding roller which is made out of gun metal, uniformly engraved and coated with food grade Teflon. Excess dough is cleared with a knife, which is held by a holder made from tool steel, to ensure uniform filling. Features

|

|

||

| Hard Dough Biscuit Equipment Hard dough biscuits are produced on lines, which consist of a sheeter and gauge rollers. The desired dough blanks are cut out by a single head rotary cutter, which prints excellent design on a continuously fed dough sheet. The resulting network of scrap dough is fed back to the sheeter. The blanks are baked in a oven on a wire mesh band.

|

|

||

Baking Oven Equipment ovens are specially designed to bake biscuits (Available F.O, Gas, Diesel & Electric, direct / indirect baking models). These ovens are indirectly heated ovens which have been developed for large number of biscuit varieties. The mediums of heat transfer provided in these ovens are Cyclotherm-Radiation. The entire construction is of sheet metal which is put together and assembled at site of installation.

|

|

||

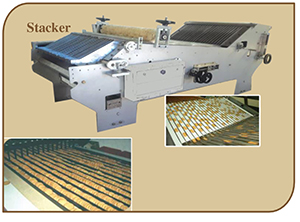

Post Backing Equipment Post Baking is the process to cool down the biscuit suitable to pack. The process involves to travel biscuit through a series of machines before the biscuit is handed over to the packing machines. Our range of post baking equipment includes stipper, cooling conveyor, feeder table, stacker and packing tables. These machines provide precise and immaculate design to the biscuits. Cooling conveyor's available in single Tire, Two Tire, Three Tire & Four Tire arrangement. |

|

||

Biscuit Stacker We are offering precisely built Biscuit Stackers that are used in bakery and food industry. It has even divisions, which make the movement of biscuits smooth from manufacturing plant to packing tables.

|

|

||

Toast Bread Plant Our company offers quality tested Toast Bread Plant, which are extensively required in bakery and food industry. Our plant is advanced in technology and high speed productivity in comparison to other plants in market. Our toast plant operates on low energy and is proven to come with longer functional life. Our machinery capacities from 50kg / hr to 500kg / hr. our plant is available with semi or fully automation. |

|

||

Raw Material Handling Equipment Our company is engaged in developing excellent range of Raw Material Handling Equipment, which is manufactured from high grade stainless steel and installed in several bakery and food processing industry. Our range of bakery handling system includes maida handling system, butter handling system, glucose handling & dosing system, flour handling & dosing system, fat & lecithin handling system. We offer this system in standard as well as in customized variety. Our plant produces accurate quantity of bakery products with consistent product quality and superior productivity. We also ensure high standard of hygiene is maintained, while manufacturing these systems. |

|